-

This is the latest model of CNC 4-axis toilet brush tufting machine with side worktable, the tufting method is anchor-type (flat wire). The major difference between WXD-4A001 and WXD-4A009 is the direction of worktable. Click to see its overall technical details.

This is the latest model of CNC 4-axis toilet brush tufting machine with side worktable, the tufting method is anchor-type (flat wire). The major difference between WXD-4A001 and WXD-4A009 is the direction of worktable. Click to see its overall technical details. -

Many suppliers use this WXD-2A005 to make plastic brooms, this is the most popular model among all our machines. Its fastest tufting speed is 7 holes per second. Its tufting method is anchor-type (flat wire), with two grippers holding two brooms on worktable.

Many suppliers use this WXD-2A005 to make plastic brooms, this is the most popular model among all our machines. Its fastest tufting speed is 7 holes per second. Its tufting method is anchor-type (flat wire), with two grippers holding two brooms on worktable. -

This WXD-4A006 is very popular among Indian customers. With two grippers holding two brushes on worktable, it tufts hockey brushes continually under "Automatic Mode", non-stop. Please note that the plastic hockey brush pieces should be molded with holes in advance.

This WXD-4A006 is very popular among Indian customers. With two grippers holding two brushes on worktable, it tufts hockey brushes continually under "Automatic Mode", non-stop. Please note that the plastic hockey brush pieces should be molded with holes in advance. -

How big is the disk brush? Dear customers, the maximum diameter of disk brush it can make is 1200mm (1.2m)! As a 2-axis machine, the filaments are tufted vertically at 90 degrees, however, the plastic disk pieces could be molded with holes tilting at angles.

How big is the disk brush? Dear customers, the maximum diameter of disk brush it can make is 1200mm (1.2m)! As a 2-axis machine, the filaments are tufted vertically at 90 degrees, however, the plastic disk pieces could be molded with holes tilting at angles. -

It's a CNC 5-axis 5-head machine of the latest design! With 6 grippers holding 6 brushes on worktable, it finishes two toilet brushes within a working cycle, which is twice that of a 5-axis 3-head machine. In program, all the positions of holes are divided averagely.

It's a CNC 5-axis 5-head machine of the latest design! With 6 grippers holding 6 brushes on worktable, it finishes two toilet brushes within a working cycle, which is twice that of a 5-axis 3-head machine. In program, all the positions of holes are divided averagely. -

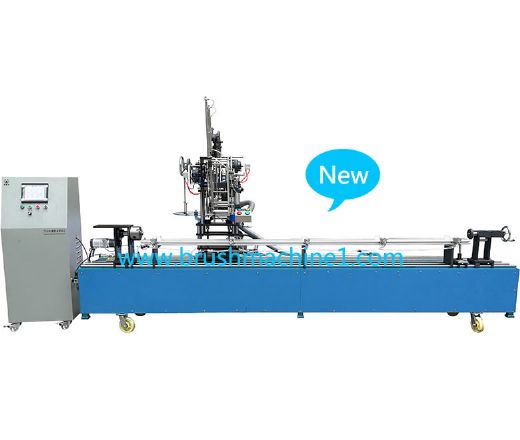

This WXD-3A2H07 is a dual-purpose machine, used to make both industrial roller brushes and flat plank brushes.The program is set up under "Parameter Mode", operator just need enter several numbers and confirm the position of the first hole, then it's finished.

This WXD-3A2H07 is a dual-purpose machine, used to make both industrial roller brushes and flat plank brushes.The program is set up under "Parameter Mode", operator just need enter several numbers and confirm the position of the first hole, then it's finished. -

Are you looking for a machine to make small roller brushes? WXD-3A3H01 would be your best choice! Many suppliers use it to make small industrial roller brushes. The maximum length of the roller allowed is 30cm, machine in bigger size could be customized.

Are you looking for a machine to make small roller brushes? WXD-3A3H01 would be your best choice! Many suppliers use it to make small industrial roller brushes. The maximum length of the roller allowed is 30cm, machine in bigger size could be customized. -

If you want to make wood shoe brushes or other small flat brushes, and the original brush blocks are just without holes, this WXD-2A3H01 could be your top choice. It drills holes and tufts filaments synchronously. The maximum length of filaments (outside holes) allowed is 120mm.

If you want to make wood shoe brushes or other small flat brushes, and the original brush blocks are just without holes, this WXD-2A3H01 could be your top choice. It drills holes and tufts filaments synchronously. The maximum length of filaments (outside holes) allowed is 120mm. -

This is our 5-axis 3-head broom making machine of the latest style! It's equipped with two drilling-heads and a tufting-head. After drilling holes, the worktable automatically transports the broom piece from drilling-head to tufting-head, which greatly saves manpower.

This is our 5-axis 3-head broom making machine of the latest style! It's equipped with two drilling-heads and a tufting-head. After drilling holes, the worktable automatically transports the broom piece from drilling-head to tufting-head, which greatly saves manpower. -

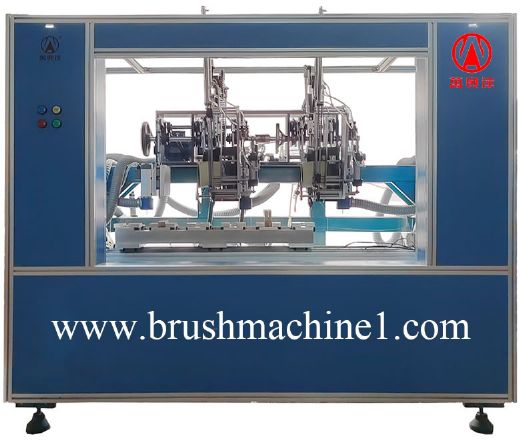

Need a wood brush machine with really high working efficiency? You might be satisfied with this 2-axis 5-head machine WXD-2A5H03. It's equipped with three drilling-heads and two tufting-heads, its hourly output is completely twice that of a 2-axis 3-head machine!

Need a wood brush machine with really high working efficiency? You might be satisfied with this 2-axis 5-head machine WXD-2A5H03. It's equipped with three drilling-heads and two tufting-heads, its hourly output is completely twice that of a 2-axis 3-head machine!

-

Wangxinda's Strong Point - Besides Standard Brush Machines, We Are Good At Customizing Non-Standard Brush Machines

As the Chief Engineer and also one of the founders, Mr Chen Jia Xing is the soul of our factory, who has been engaged in design and production of CNC brush machines ever since the graduation from school. Till now, Mr Chen has accumulated over 20 years' experience in production of brush machines and become one of the most famous entrepreneurs in the field of brush making machines in China.

Particularly Mr Chen is extremely good at developing non-standard machines for different customers, such as 1-axis 2-head machine for making strip brushes with only a line of holes and dualpurpose 3-axis 2-head machine for making both roller brushes and plank brushes, etc.

In conclusion, we are completely capable of customizing non-standard machines exactly according to customer's production requirements, not to speak of those standard machines used for making daily cleaning brushes, such as 2-axis high-speed broom tufting machine and 5-axis 3-head brush drilling and tufting machine, etc.

Wangxinda's Customers - Before 2008, we mainly specialized in domestic market, 95% of the brush making machines were sold to our Chinese customers, only about 5% were exported to foreign countries through some trading companies. However, we actively started developing international market from 2008, by means of promoting our own English website.

Thanks to the internet promotion, we finally entered the international market gradually and successfully. So far we have developed a great many international customers distributed in every corner of the world, such as South America (Colombia, Chile, Venezuela, Brazil, Bolivia, Peru), North America (Mexico, Canada), East Europe (Russia, Turkey, Belarus), North Europe (Finland), West Europe (UK), East Asia (Korea), Southeast Asia (Vietnam, Indonesia, Thailand, Philippines), South Asia (Sri Lanka, Pakistan, India), North Africa (Tunisia, Morocco, Egypt), South Africa, etc.

-

2024.04.15It was really a busy week. Just after the holidays for the Tomb Sweeping Day, two batches of Indian customers came to our factory at the same time, for the purpose of inspection and training for brush machines they ordered. The mis

-

2024.01.12There is an old Chinese saying that it is such a delight to have friends coming from afar! On the morning of Jan 08, 2024, we greeted both Mr Wang from Shandong province of China and Mr Aka*** from Bangkok of Thailand, who came to our factory to

-

2023.09.18Being a national exhibition of brush industry and the largest brush industry exhibition in the world, the third China International Brush Making Industry Exhibition (CIBRUSH) was successfully held in Shenzhen from Sep.13, 2023 to Sep.15, 2023, which

-

2023.08.04According to those economists, the lifting of pandemic restrictions would eventually usher in a strong economic rebound, as the country learned to live with the Covid-19 virus. However, those Covid-19 cases indeed subsided in the past several months,

-

2023.06.25Since covid-19 swept across the world in 2019, it had a profound impact on the global economy. All the major industries and services were seriously affected by the crisis from 2019.12 to 2022.12, so were we!! Fortunately, since our government lif

-

2017.12.22In this festive season, we met a respected customer from Pakistan -- Mr Azhar Masood, who came to our workshop to accept the training for his 3-axis brush tufting machine for the first time. Mr Azhar is completely a green hand with brush ma

-

How To Select A Brush Machine

An experienced operator probably already knows these very well, however, a new hand may find these tips useful.

The basic principle is selecting brush machines according to the shapes of brush models.

1) Normally flat brushes are made by 2-axis machines. For example, this WXD-2A005 is a 2-axis tufting machine used to make flat plastic brooms, flat scrub brushes and other flat cleaning brushes.

2) As for 3-axis machines, in most cases they are used to produce curved brushes, round brushes and roller brushes. For example, this WXD-3A003 is a 3-axis tufting machine for making curved toilet brushes; this WXD-3A3H03 is a 3-axis machine used to produce industrial roller brushes; and this is also a 3-axis machine tufting round body-cleaning brushes.

3) With an axis supporting up/down movements of the worktable, 4-axis machines are often used to produce those more tridimensional brush models, such as spherical toilet brushes, double-side hockey brushes, convex vegetable-cleaning brushes and wavy brooms.

4) As to 5-axis machines, well, with 5 axes, they are the most flexible ones, they can make almost all kinds of brush models within the size range, no matter the brushes are flat, curved, fan-shaped, round, spherical or wavy. That's also why 5-axis machines are the most expensive ones.

Of course the most convenient way is directly contacting us at chloe@brushmachine1.com, we'll do our best to provide you with a professional proposal for brush production.

-

Hot Brush Machine Models

So far we've already sold thousands of CNC brush making machines. According to our sales records, here are the most popular brush machine models ordered by worldwide customers in the past 13 years:

1) 2-Axis high-speed broom tufting machine -- It's absolutely the top 1 on the list of our best-selling machines. Many manufacturers from East Asia, Southeast Asia and South Asia use this model to produce flat plastic brooms, scrub brushes and other flat daily cleaning brushes.

2) 4-Axis toilet brush tufting machine -- The reason why it's ranked second is that most manufacturers who produce plastic brooms also make round toilet brushes, therefore 4-axis toilet brush tufting machines also become necessary models in the workshops of most producers.

3) 5-Axis 3-head brush drilling and tufting machine -- Definitely it's the top choice for manufacturers who produce quality plastic brooms, environment-friendly wood brooms and round toilet brushes. Please also note that those qualilty brooms made by a 5-axis 3-head machine are usually much more expensive than those plastic brooms tufted by a 2-axis machine.

4) 2-Axis long-roller brush drilling and tufting machine -- It's the typical model for making those big and long industrial roller brushes. The length of a big roller brush piece could be 3 metres, and the longest roller brush model we once made according to customer's requirement was 4 metres long! Normally, those long industrial roller brushes are used to clean metal surfaces, polish fruits & vegetable, polish leather surface, fabric, etc.

Besides the best-selling brush machines, we also customize machines for customers who have different and special production requirements, please do not hesitate to contact us, we are completely ready for your case!