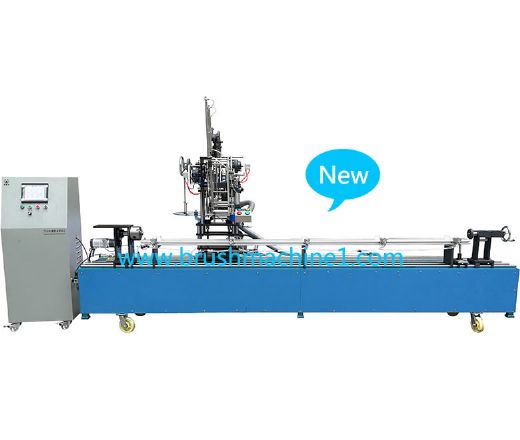

General Introduction Of Clothes Washing Brush Making Machine WXD-3AAU01

Compared with other normal brush machine models, this clothes washing brush making machine WXD-3AAU01 is much more automatic! Those plastic brush bases are automatically fed into grippers one piece by one piece, and then the rotary grippers convey the brush bases to be tufted and trimmed automatically. After tufting and trimming, those finished clothes washing brushes also automatically fall off.

In a word, automatic feeding, tufting and trimming are integrated together! Please click here to watch the video demonstration, you'll easily understand how it works.

Which Brush Models Can This WXD-3AAU01 Make?

This WXD-3AAU01 is designed to make a single flat brush model only. It can't make other different brush models.

What's The Advantage Of This Clothes Washing Brush Making Machine WXD-3AAU01?

Since it's more automatic, the manpower needed is greatly decreased, which finally helps the manufacturer save the labor cost significantly!

For normal brush machines, it's known that each operator is responsible for running a machine separately. However, if using this WXD-3AAU01 in production, an operator is completely capable of running two or three sets of machines at the same time, thus fewer workers are needed and the labor cost is enormously decreased.

What Other Jobs Should The Operator Do?

The operator still needs to manually put plastic brush bases on the stacking area and add brush filaments from time to time, that's all! It's easy, that's why an operator is able to run two or three sets of machines simultaneously!

Still having some further questions or doubts about this automatic brush machine WXD-3AAU01? Please do not hesitate to contact us at chloe@brushmachine1.com or just directly leave a message on this page, it'll be our great pleasure to hear from you and we'll try our best to reply to you with a professional solution at the earliest.

Technical Parameters Of 3-Axis Clothes Washing Brush Making Machine WXD-3AAU01

| Standard Processing Area | X-axis x Y-axis x Z-axis = 250mm x 150mm x 360° |

| Materials Of Brush Bases | Plastic |

| Materials Of Brush Filaments | PP, PVC, PET, nylon, tampico, steel wires, copper wires, horse hair, buffalo hair |

| Length Of Brush Filaments | 10mm - 110mm (outside holes) |

| Diameter Of A Single Filament | 0.08mm - 1.8mm |

| Diameter Of Holes | 2mm - 6mm |

| Colors of Filaments | Either 1 color or 2 colors |

| Maximum Tufting Speed | 6 Holes per second |

| Tufting Method | Anchor type (flat wire) |

| Motors & Drivers | Panasonic servo motors and Panasoinc drivers |

| Programming | Hole positions are manually entered by hand-controller, one hole by one hole |

| Brush Models Processed | Customized to make a single flat brush model only |

| Touchable Screen | Big touchable screen, interface is in English and Chinese, other language could be customized |

| Adjusting Speed | Variable-frequency stepless adjustable speed |

| Power Supply | Single-phase 220V or 3-phase 380V, 50-60Hz, 750W |

| Packing | Wood case for machine body: 1.22m (Length) x 1.12m (Width) x 2.1m (Height); Wood case for computer: 0.57m (Length) x 0.57m (Width) x 1.46m (Height); |

| Volumn | 2 Packages (Wood Cases), 3.34CBM |

| Gross Weight | Around 620KGS |

Maintenance of Automatic 3-Axis Clothes Washing Brush Making Machine WXD-3AAU01

1) Operator should often add lubrication oil to the working parts of this clothes washing brush making machine, so as to decrease abrasion.

2) Operator should regularly check each part to see whether there is a loose screw, and please make sure to tighten it, if he finds a loose one.

3) Please keep guide rails and ballscrews clean, and make sure that there is no scrap sticking on them, so as not to decrease the precision.

4) Be sure that the electric box works under ventilative conditions; do not put this brush machine under humid or high-temperature conditions; do not shake the electric box.

5) Please keep electric box far away from magnetic field, otherwise it will be probably out of control.

6) Be sure that all cables connect correctly. Red, blue and yellow cables connect with three-phase 380V wires, green cable connects with neutral wire, yellow-green cable connects with earth wire. Plugs are numbered as "1, 2, 3, 4 , 5", "1, 2, 3" are for 3-phase 380V wires, "4" is for neutral wire, "5" is for earth wire.

7) The working voltage should be stable, around AC380±10V; over-voltage will probably cause the ruin of electronics.

8) Do not knock at the touchable screen with hard articles, otherwise it'll decrease its sensibility or even break the screen.

9) Please note that there is high-voltage electricity inside electric box. If this brush making machine is out of order, only professional electricians are allowed to check and dismantle it. Non-professionals are prohibited to dismantle it, so as to avoid getting an electric shock and the ruin of data.

10) Do not drag wires rudely.