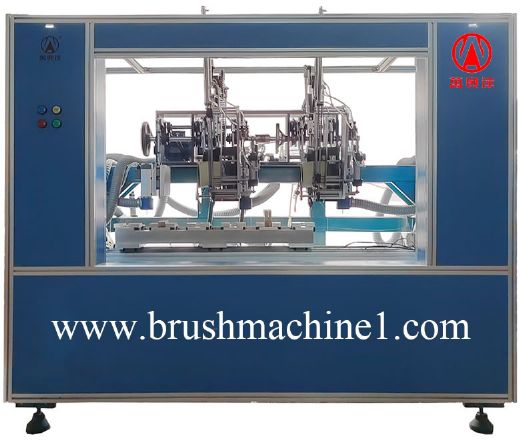

General Introduction Of Manual Broom Trimming & Flagging Machine WXD-TM900

1) This manual broom trimming and flagging machine WXD-TM900 is a very popular model among broom manufacturers. It's equipped with two sets of flagging blades and a set of trimming blade inside. After trimming and flagging, all the broom filament-ends are not only flat and neat, but also split into many small strips like these:

2) Both trimming and flagging are controlled by separate switches, operator could select to use two functions together, or use only one of the functions, either trimming or flagging.

3) The blades are made of imported steel with excellent tenacity, which are abrasion-resistant. The blades could rotate in both clockwise and counterclockwise directions, which are controlled by the switches installed aside. Please keep in mind that operator should put nothing on the blades before they start rotating.

4) This machine processes brooms with filaments made from PP, PVC, PET, nylon, pig bristles, tampico, etc, the diameter of a single filament should not be thicker than 1.2mm.

5) Please be informed that it is not allowed to trim brushes with stainless steel wires, copper wires or abrasive wires.

Technical Parameter of Manual Broom Trimming And Flagging Machine WXD-TM900

1) Item No.: WXD-TM900

2) Power Input: 0.55KW

3) Voltage: 380V, ±10% is allowed

4) Motor Rotation: 1400RMP

5) Rated Frequency: 50Hz

6) Specification: 60cm(Length) * 40cm(Width) * 60cm(Height)

7) Daily Continuous Working Time: 24Hours

8) Gross Weight: 50KGS

9) Packing: Wooden Case

Operation:

1) Before starting this broom trimming & flagging machine, please check whether all the working parts and guide rails are installed correctly and firmly.

2) On the worktable, there are two indispensable guide rails supported by four columns, which are fixed by screws. By twisting those four screws, operator adjusts not only the height between guide rails and tabletop, but also the gap distance between two guide rails. It is forbidden to directly put a broom on blade without using guide rails.

3) After switching it on, operator should wait for a moment until the blades start rotating regularly.

4) Operator deposits the broom into the gap between two guide rails, and then slowly pushes it back and forth along the guide rails one or two times.

Maintenance Of Broom Trimming And Flagging Machine WXD-TM900

1) Operator should keep this broom trimming & flagging machine clean, and often spray the blades with anti-rust agent.

2) If the blades become blunt, please smear the blades with diamond paste, and then switch it on to make the blades rotate in counterclockwise direction for 5 to 10 minutes. Please note that diamond paste should be wiped out thoroughly after grinding.

3) Operator should regularly check each part to see whether there are loose screws or not, and please make sure to tighten it if he finds a loose one, so as to avoid any accident.

4) If this manual trimming & flagging machine is always deposited in a humid environment, please check whether there is leakage of electricity around the motor before usage. If operator feels leakage of electricity, please make sure to dry it thoroughly before running, so as to keep safe.