Which Brushes Can WXD-1A2H01 Make?

| Brush Shapes | Strip brushes with only a line of holes |

| Drilled Holes | Original plastic strip brush pieces are without holes, holes are to be drilled by this machine |

| Angle of Holes | Holes are vertical to brush surface at 90 degrees only, holes can't be tilting at angles |

| Brush Size | There is no limit to the length of strip brush piece |

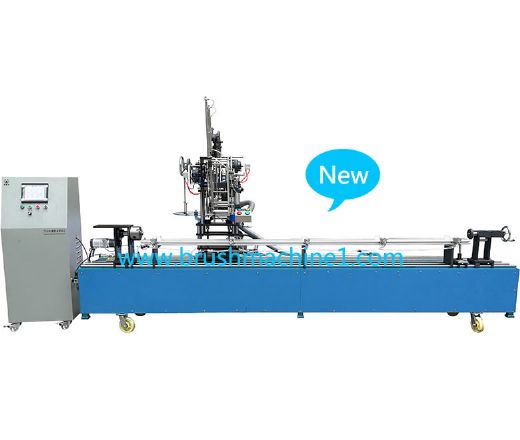

General Introduction of CNC 1-Axis 2-Head Plastic Strip Brush Making Machine WXD-1A2H01

1) This WXD-1A2H01 has a drilling-head and a tufting-head, which drills holes and tufts filaments synchronously, used to make plastic strip brushes with only a line of holes, please note that it cannot make strip brushes with two lines of holes. (If you are interested to make strip brushes with more than two lines of holes, another 2-axis strip brush machine is recommended)

2) No matter the strip brush piece is 20m, 50m, 100m or even 200m long, this machine can process it smoothly without any problem, there is just no limit to the length of the strip brush pieces! Its tufting method is staple-type (round wire).

3) With servo motor, the fastest working speed is 5 holes per second.

4) On the video demonstration, it's making a red plastic strip brush with tampico filaments, drilling and tufting at the same time! If you are quite interested in this 1-axis strip brush making machine, please do not hesitate to contact us at chloe@brushmachine1.com or just leave a message on this page, it'll be our great pleasure to hear from you.

Technical Parameters of 1-Axis 2-Head Industrial Strip Brush Making Machine WXD-1A2H01

| Standard Processing Area | No limit to the length of strip brush pieces |

| Materials of Brush Pieces | Plastic, wood |

| Materials of Brush Filaments | PP, PVC, PET, nylon, pig bristles, stainless steel wires, copper wires, horse hair, tampico |

| Length of Filaments | 10mm - 120mm (outside holes) |

| Diameter of A Single Filament | 0.08mm - 1.2mm |

| Diameter of Holes | 3mm - 6mm |

| Colors of Filaments | Either 1 color or 2 colors |

| Maximum Working Speed | 5 Holes per second |

| Tufting Method | Staple type (round wire) |

| Motors | Panasonic servo motors |

| Programming | Hole positions in each line are divided averagely by "Divide" button in program |

| Quantity of Programs Saved | It saves totally 84 programs for different brush models |

| Changeable Grippers | Operator could make many other strip brush models, as long as he changes grippers accrodingly |

| Hitech Touchable Screen | 5.4'' touchable screen, interface is in English and Chinese, other language could be customized |

| Adjusting Speed | Variable-frequency stepless adjustable speed |

| Power Supply | Single-phase 220V or 3-phase 380V, 50-60Hz, 600W |

| Packing | Wood case for machine body: 3.5m (Length) x 0.9m (Width) x 1.7m (Height) Wood case for computer: 0.65m (Length) x 0.65m (Width) x 1.5m (Height) |

| Gross Weight | Around 300KGS |

Maintenance of 1-Axis 2-Head Industrial Strip Brush Drilling And Tufting Machine WXD-1A2H01

1) Operator should often add lubrication oil to the working parts of this strip brush machine, so as to decrease abrasion.

2) Operator should regularly check each part to see whether there is a loose screw, and please make sure to tighten it, if he finds a loose one.

3) Please keep guide rails and ballscrews clean, and make sure that there is no scrap sticking on them, so as not to decrease the precision.

4) Be sure that the electric box works under ventilative conditions; do not put this strip brush machine under humid or high-temperature conditions; do not shake the electric box.

5) Please keep electric box far away from magnetic field, otherwise it will be probably out of control.

6) Be sure that all cables connect correctly. Red, blue and yellow cables connect with three-phase 380V wires, green cable connects with neutral wire, yellow-green cable connects with earth wire. Plugs are numbered as "1, 2, 3, 4 , 5", "1, 2, 3" are for 3-phase 380V wires, "4" is for neutral wire, "5" is for earth wire.

7) The working voltage should be stable, around AC380±10V; over-voltage will probably cause the ruin of electronics.

8) Do not knock at the touchable screen with hard articles, otherwise it'll decrease its sensibility or even break the screen. Do not drag wires rudely, either.

9) Please note that there is high-voltage electricity inside electric box. If it is out of order, only professional technicians are allowed to check and dismantle it. Non-professionals are prohibited to dismantle it, so as to avoid getting an electric shock and the ruin of data.